EMSTEEL Group in the UAE has launched the world’s first industrial-scale electric process gas heater pilot, aiming to cut over 2,200 tonnes of CO₂ annually and set new standards in sustainable steel production.

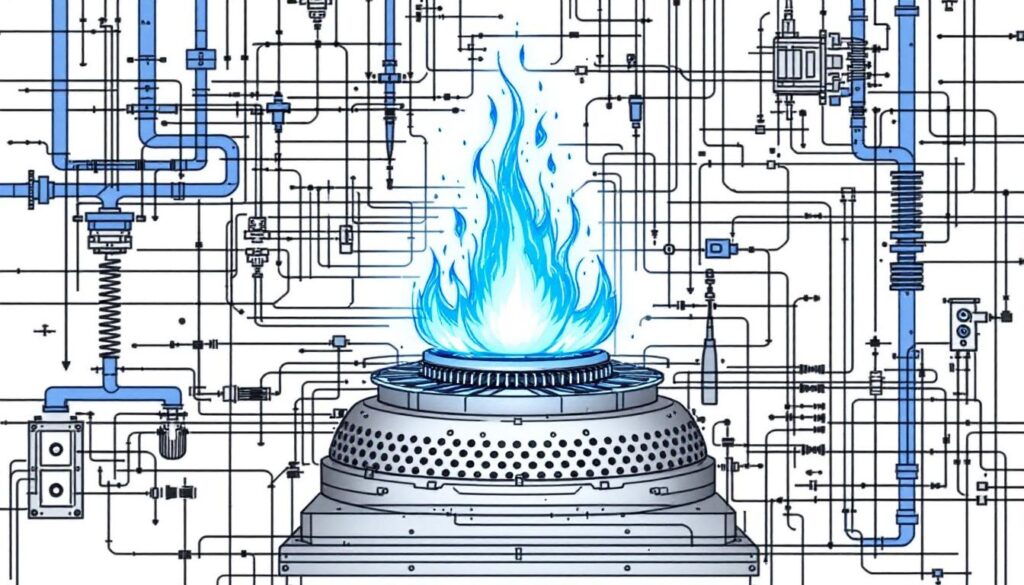

EMSTEEL Group, which is one of the leading steel and building materials manufacturers in the UAE, has recently kicked off a pretty groundbreaking pilot project — they’re testing out the world’s first electric process gas heater (ePGH) for steelmaking. It’s quite an achievement, especially since they’ve been working closely with Danieli, a global leader in industrial technology. This initiative is seen as a major step forward in reducing carbon emissions within the steel industry.

Basically, the ePGH replaces traditional gas-fired heaters at EMSTEEL’s Direct Reduced Iron (DRI) plant located in Abu Dhabi, using a clean electric technology instead. And it’s not just a small change — this switch could eliminate over 2,200 tonnes of CO₂ emissions every year. That’s pretty significant. It aligns perfectly with EMSTEEL’s broader goal of cutting emissions by 40% by the year 2030 across its steel business. Plus, it supports the UAE’s ambitious Net Zero by 2050 initiative and the country’s ‘Operation 300 billion’ industrial strategy—so it’s part of a bigger national effort.

The development of the ePGH system was a real team effort, with close cooperation between EMSTEEL and Danieli’s R&D crews. The system has undergone extensive testing to ensure it can handle tough industrial conditions and deliver reliable performance. The initial pilot uses a 1.3-megawatt unit, but there are plans to potentially scale this up to a massive 22.7-megawatt version. If successful, this could not only change how thermal process heating is done in steelmaking but also set an industry-wide example for large-scale electric upgrades.

Kanthal, a division of Alleima, and Danieli are jointly supplying this pilot heater. It includes Kanthal’s innovative Prothal® DH technology — a solution designed to boost energy efficiency and completely eliminate the CO₂ emissions that usually come from burning fossil fuels in heating processes. The plan is to deliver the first unit by early 2026, putting the UAE right at the forefront of adopting cutting-edge sustainable manufacturing techniques.

Engineer Saeed Ghumran Saeed Al Remeithi, the Group CEO at EMSTEEL, emphasizes that the company’s push toward scalable clean tech is about leading the way in sustainable manufacturing in the region. “By adopting scalable clean technologies, we’re not only speeding up our own green steel journey,” he explained, “but also reinforcing the UAE’s standing as a global innovation hub for industry.” He added that their ultimate goal is to create solutions that have a lasting positive impact on the environment, the economy, and future generations.

EMSTEEL is already impressive — operating 16 high-tech plants that produce around 3.5 million tonnes of steel and 4.6 million tonnes of cement each year. Their products support major infrastructure projects within the UAE and in over 70 international markets. The company’s efforts to cut emissions have already seen a 23% reduction in Scope 1 and Scope 2 emissions intensity. As of 2023, their total Scope 1 and 2 emissions totaled about 4.5 million tonnes of CO₂, marking real progress toward their net-zero targets.

This electric heater project isn’t just about environmental benefits. It’s also scalable and could be applied across the steel industry worldwide. Replacing fossil fuel-based thermal processes with electric systems powered by renewable energy is seen as a pretty pivotal move toward overall decarbonisation.

Industry data shows that steel manufacturing has historically been responsible for roughly 7-9% of global CO₂ emissions since it’s such an energy-heavy, carbon-intensive industry. Innovations like EMSTEEL’s ePGH could be a game-changer—especially for regions that are aiming to decarbonise through clean energy adoption. If this pilot proves successful, it might well encourage similar retrofits around the globe, helping to decarbonise steel production at a larger scale.

The project also strengthens Abu Dhabi and the UAE’s reputation as players in sustainable industrial innovation. Backed by ADQ, a sovereign investment firm focused on key infrastructure and supply chains, EMSTEEL demonstrates what’s possible when public and private sectors team up to promote climate-friendly tech.

As the delivery date nears, a lot of attention will be focused on how the pilot performs operationally, particularly in terms of energy efficiency. The insights gained could influence the future of steel manufacturing—not just here in the Middle East but around the world. By proving that electric heating can handle the demands of heavy industry, EMSTEEL and its partners are paving the way toward a cleaner, more sustainable industrial future.

Source: Noah Wire Services

- https://www.zawya.com/en/press-release/companies-news/emsteel-launches-the-worlds-first-pilot-of-electric-process-gas-heaters-in-steelmaking-qwu0p220 – Please view link – unable to able to access data

- https://www.danieli-usa.com/en/news/emsteel-proceeds-dri-carbon-reduction-program-danieli_13_966.htm – EMSTEEL has initiated a pilot project to install an electric Process-Gas Heater (e-PGH) at its Direct Reduced Iron (DRI) plant in Abu Dhabi, UAE. This collaboration with Danieli aims to replace conventional gas-fired heaters with an electric alternative, reducing over 2,200 tonnes of CO₂ emissions annually. The project is part of EMSTEEL’s broader decarbonisation strategy, which includes a commitment to reduce emissions by 40% by 2030 in its steel division. The e-PGH system, developed jointly with Danieli, has undergone extensive testing to ensure optimal performance under industrial conditions.

- https://www.aist.org/electric-process-gas-heater-to-be-supplied-by-kanthal-and-danieli – Kanthal and Danieli are collaborating to supply a pilot-scale electric process gas heater for installation at EMSTEEL’s DRI plant in Abu Dhabi, UAE. The heater, based on Kanthal’s Prothal® DH technology, represents the first electric process gas heater for DRI that Kanthal will supply for commercial use. Scheduled for delivery in early 2026, this technology aims to eliminate CO₂ emissions from the heating process while enhancing energy efficiency, marking a significant step in industrial decarbonisation efforts.

- https://www.prnewswire.com/news-releases/alleimas-kanthal-division-and-danieli-to-supply-first-electric-process-gas-heater-for-commercial-use-in-dri-302464114.html – Alleima’s Kanthal division and Danieli have announced a partnership to supply a pilot-scale electric process gas heater for installation at EMSTEEL’s DRI plant in Abu Dhabi, UAE. This heater, based on Prothal® DH technology, will be the first electric process gas heater for DRI supplied by Kanthal for commercial use. The delivery is planned for early 2026, and the technology aims to completely remove CO₂ emissions from the heating process while enhancing energy efficiency, supporting EMSTEEL’s commitment to sustainable manufacturing.

- https://www.danieli.com/en/news-media/news/EMSTEEL-proceeds-with-DRI-carbon-reduction-program-with-Danieli_37_966.htm – EMSTEEL is advancing its decarbonisation efforts by installing an electric Process-Gas Heater (e-PGH) at its DRI plant in Abu Dhabi, UAE. This initiative, in collaboration with Danieli, aims to replace traditional gas-fired heaters with an electric alternative, reducing over 2,200 tonnes of CO₂ emissions annually. The e-PGH system, developed jointly with Danieli, has undergone rigorous testing to ensure optimal performance under industrial conditions, marking a significant step in EMSTEEL’s commitment to sustainable manufacturing.

- https://www.alleima.com/en/news-media/archive/2025/05/alleimas-kanthal-division-and-danieli-to-supply-first-electric-process-gas-heater-for-commercial-use-in-dri/ – Alleima’s Kanthal division and Danieli are collaborating to supply a pilot-scale electric process gas heater for installation at EMSTEEL’s DRI plant in Abu Dhabi, UAE. The heater, based on Prothal® DH technology, will be the first electric process gas heater for DRI supplied by Kanthal for commercial use. Scheduled for delivery in early 2026, this technology aims to eliminate CO₂ emissions from the heating process while enhancing energy efficiency, supporting EMSTEEL’s commitment to sustainable manufacturing.

- https://www.kanthal.com/it/knowledge-hub/news/kanthal-danieli-electric-process-gas-heater/ – Kanthal and Danieli are collaborating to supply a pilot-scale electric process gas heater for installation at EMSTEEL’s DRI plant in Abu Dhabi, UAE. The heater, based on Prothal® DH technology, will be the first electric process gas heater for DRI supplied by Kanthal for commercial use. Scheduled for delivery in early 2026, this technology aims to eliminate CO₂ emissions from the heating process while enhancing energy efficiency, supporting EMSTEEL’s commitment to sustainable manufacturing.

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative was first published on May 23, 2025, by Alleima’s Kanthal division and Danieli, announcing the supply of a pilot-scale electric process gas heater to EMSTEEL’s DRI plant in Abu Dhabi. ([alleima.com](https://www.alleima.com/en/news-media/archive/2025/05/alleimas-kanthal-division-and-danieli-to-supply-first-electric-process-gas-heater-for-commercial-use-in-dri/?utm_source=openai)) The Zawya article appears to be a republished version of this press release, with no significant new information added. The presence of the same figures and quotes across multiple low-quality sites suggests recycled content. The original press release, being a direct announcement from the involved companies, warrants a high freshness score. However, the Zawya article’s lack of new insights and its dissemination across various low-quality platforms indicate a lower freshness score.

Quotes check

Score:

9

Notes:

The direct quotes from Engineer Saeed Ghumran Al Remeithi, Group CEO at EMSTEEL, and Robert Stål, President of the Kanthal division, are identical to those in the original press release. No variations or new quotes are present, indicating potential reuse of content.

Source reliability

Score:

6

Notes:

The original press release from Alleima and Danieli is from reputable organisations, lending credibility to the information. However, the Zawya article is a republished version of this press release and appears on various low-quality sites, which may affect its reliability.

Plausability check

Score:

8

Notes:

The claims about EMSTEEL’s pilot project to install an electric process gas heater at their DRI plant in Abu Dhabi align with the original press release. The technical details and quotes are consistent, and the project is plausible within the context of EMSTEEL’s ongoing efforts to reduce carbon emissions. The lack of new information or updates in the Zawya article does not raise significant concerns about its plausibility.

Overall assessment

Verdict (FAIL, OPEN, PASS): FAIL

Confidence (LOW, MEDIUM, HIGH): HIGH

Summary:

The Zawya article is a republished version of an earlier press release from May 23, 2025, with no significant new information added. The identical quotes and figures, along with its appearance across various low-quality sites, suggest recycled content. While the original press release from reputable organisations is credible, the Zawya article’s lack of originality and dissemination across low-quality platforms indicate a lower reliability score.