A joint review from the American University of Sharjah and Heriot‑Watt finds that improved solvents, electrochemical regeneration and advanced sorbents could cut the energy and cost penalties of industrial carbon capture — yet material durability, industrial purity targets and infrastructure needs mean pilots and policy will determine whether regional ambitions reach gigatonne scale by the 2030s.

A joint review by the American University of Sharjah and Heriot‑Watt University sketches a brighter, though still cautious, horizon for carbon capture in the Gulf. The paper surveys recent progress in solvent chemistry, sorbent materials and electrochemical regeneration, arguing that a new generation of capture technologies could meaningfully shrink the energy and cost penalties that have long slowed deployment in heavy industries such as oil and gas, cement and steel. Honestly, the authors aren’t promising a miracle, just a clearer path forward.

According to the Nature Reviews Chemistry article co‑authored by Maroto‑Valer and Dr Steve Griffiths, the most immediate gains stem from incremental chemistry improvements to well‑established solvent systems. Traditional monoethanolamine (MEA) capture plants, the review notes, burn through roughly 0.9–1.2 MWh to regenerate solvents for every tonne of CO2 captured—energy that can account for as much as 80% of operating costs. But blended amine formulations, such as MEA/MDEA mixes, and “water‑lean” or phase‑splitting solvents can substantially cut that regeneration burden. Speaking to Technical Review Middle East, Dr Griffiths—professor and vice‑chancellor for research at AUS—described blended amines as “the most established carbon‑capture technology,” with MEA/MDEA blends achieving over 30% reductions in regeneration energy compared with single solvents. This approach—well, it does seem to offer a pretty meaningful head start.

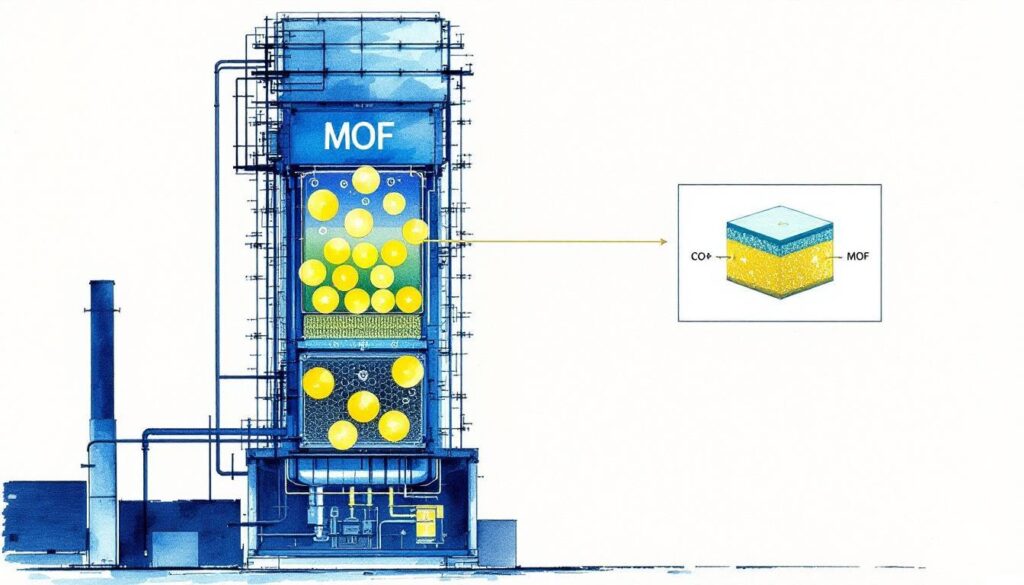

Beyond tweaks to existing chemistries, the review highlights more disruptive routes that are moving from laboratory curiosity toward pilot demonstration. Electrochemical regeneration and electroswing systems promise to replace thermal reboilers with electrically driven cycles, reducing the need for heat and enabling better coupling with renewables. Metal‑organic frameworks (MOFs) and other advanced solid adsorbents offer much higher surface areas and lower theoretical regeneration energies than liquids; they are already being piloted at industrial sites. The authors caution, however, that material stability, scalability and the ability to meet industrial purity and recovery targets remain significant barriers. The review stresses that ambitious performance goals—such as achieving 90% CO2 recovery at 95% purity—are still largely aspirational for many of these novel approaches.

The American University of Sharjah framed the paper’s findings in regional policy terms, noting that these chemistry advances could dovetail with Gulf strategies to decarbonise hard‑to‑abate sectors. In a university press release, Dr Griffiths linked the technologies to the UAE’s plans for low‑carbon hydrogen and industrial decarbonisation, saying carbon capture “is central to the sustainability and economic plans of the UAE and the broader GCC.” You see, policy and science are getting bundled together here, and that matters.

Industry plans and government targets already reflect that strategic thinking. ADNOC says it intends to capture roughly 10 million tonnes of CO2 per year by 2030 and has outlined a US$15 billion investment envelope for low‑carbon projects through that date, covering carbon capture, hydrogen, electrification and renewables. Saudi Arabia has set an even larger ambition: government and industry plans summarized by the Global CCS Institute project the development of about 44 million tonnes per annum of capture capacity by 2035, anchored to proposed hubs around Jubail and Yanbu. QatarEnergy, in a memorandum with GE Vernova, is pursuing CCUS expansion to exceed 11 million tonnes per annum by 2035 and is exploring a world‑scale hub at Ras Laffan to lower LNG carbon intensity, GE Vernova’s press release states. Well, the scale of commitment here is striking, no doubt about it.

Pilot projects are testing whether the laboratory promise withstands real‑world conditions. In the UK, Drax is trialling MOF‑based capture on biomass flue gas at an incubation site in North Yorkshire, with government innovation funding backing prototype work to assess capture rates and techno‑economic performance. Those pilots underline a common theme in the literature and the review: novel sorbents and electrochemical systems can lower theoretical energy requirements, but their techno‑economic competitiveness hinges on durability, scale‑up and integration costs that are not yet fully proven. This is where the rubber meets the road, and honestly, the outcome isn’t guaranteed.

That caution is echoed by independent analysts. The Global CCS Institute has emphasised the engineering, pipeline and storage infrastructure required to make hub‑scale capture practical, noting that financing, regulation and long‑term storage liability frameworks will be decisive for Gulf ambitions. In short, the chemical advances give policymakers and operators better tools—but they do not eliminate the need for industrial planning, risk capital and regulatory clarity.

The economics are moving in a favorable direction for some applications. The AUS/Heriot‑Watt review and accompanying coverage point to scenarios in which capture costs for natural gas‑fired streams might fall to around US$50 per tonne under optimistic assumptions about solvent performance and regeneration energy. Those figures, if realized at scale, would change the calculus for coupling capture with hydrogen production and blue‑hydrogen strategies being evaluated across the region. Still, the review and industry observers underline that cost estimates depend sensitively on feedstock composition, plant integration, energy prices and whether CO2 transport and storage are available at scale. It’s not a slam dunk; there are still big moving parts.

For the Gulf, where hydrocarbon industries and energy‑intensive manufacturing are central to national economies, the implications are straightforward: improved capture technologies broaden the policy menu. They make it easier to contemplate low‑carbon hydrogen production, to lower the lifecycle emissions of LNG and petrochemicals, and to decarbonise cement plants that otherwise lack zero‑carbon alternatives. But translating lab‑scale gains into tens of millions of tonnes of capacity that countries have targeted by 2030–2035 will require coordinated investment, demonstration projects and supply‑chain development. As the Nature review puts it, chemistry advances are “unlocking new pathways,” but scale‑up, material stability and purity targets remain the critical next phase.

In short, the Gulf now has both technical reasons for optimism and a practical to‑do list. New solvents, electroswing and MOF‑based systems could cut energy and costs enough to move carbon capture from niche to mainstream in particular industrial settings. Yet universities, developers and state actors will need to prove those gains in multi‑year demonstrations, tie them to carbon transport and storage infrastructure, and mobilise the financing and regulatory arrangements that turn pilot promise into gigatonne‑scale deployment by the 2030s. It’s a tall order, but not an impossibility, if the right mix of policy backing and real‑world testing comes together.

Source: Noah Wire Services

- https://carbonherald.com/uae-led-research-highlights-next-gen-carbon-capture-breakthroughs/?utm_source=rss&utm_medium=rss&utm_campaign=uae-led-research-highlights-next-gen-carbon-capture-breakthroughs – Please view link – unable to able to access data

- https://www.nature.com/articles/s41570-025-00733-3 – The Nature Reviews Chemistry review ‘Chemistry advances driving industrial carbon capture technologies’ examines recent chemical innovations that could transform industrial carbon capture. Authored by Maroto‑Valer, Griffiths and colleagues, it surveys absorption, adsorption, membrane, cryogenic and electroswing approaches, emphasising solvent chemistry, adsorbents such as metal–organic frameworks (MOFs) and electrochemical regeneration. The article discusses performance metrics, deployment status and research gaps for hard‑to‑abate sectors including cement, steel and petrochemicals. It highlights amine blends, water‑lean and phase‑splitting solvents, and electroswing systems as promising routes to cut energy and costs, while noting scale‑up, material stability and purity targets remain challenges for industrial adoption. urgently.

- https://www.aus.edu/media/news/recent-advances-in-chemistry-are-unlocking-new-pathways-for-industrial-carbon-capture-american-university-of-sharjah-and-herriot-watt-study-finds – The American University of Sharjah press release describes a collaborative review with Heriot‑Watt University, reporting on chemistry advances that enable industrial carbon capture. Co‑authored by Dr Steve Griffiths, the piece summarises findings from the Nature Reviews Chemistry article, noting applications for oil, gas, cement and other heavy industries. It highlights novel amine blends, metal‑organic frameworks and electroswing approaches that can substantially lower regeneration energy and costs. The release quotes Griffiths on the importance of carbon capture for UAE and regional decarbonisation, and outlines the review’s aim to provide performance parameters to guide research and help scale up technologies for deployment.

- https://www.adnoc.ae/en/towards-net-zero/decarbonizing-our-operations – ADNOC’s decarbonisation pages detail the company’s low‑carbon strategy, including a stated ambition to capture approximately 10 million tonnes of CO2 annually by 2030. The site outlines a US$15 billion investment plan for low‑carbon projects through 2030 covering carbon capture, hydrogen, electrification and renewables, and highlights existing operations such as Al Reyadah and new projects like the planned fully sequestered CO2 injection well. ADNOC emphasises carbon capture as central to its Net Zero by 2050 ambition and describes specific projects, targets and partnerships to scale capture and storage in Abu Dhabi and beyond. The page includes technical and investment milestones. details

- https://www.globalccsinstitute.com/resources/insights/saudiarabiaccsefforts/ – The Global CCS Institute analysis summarises Saudi Arabia’s ambitious CCUS plans, citing government targets to develop 44 million tonnes per annum (Mtpa) of carbon capture capacity by 2035 as part of broader net‑zero commitments. The piece explains major projects such as the Jubail CCUS hub, Aramco’s storage plans and regional hubs in Jubail and Yanbu, and describes engineering, pipeline and storage plans to support industrial clusters. It assesses policy, technical and financing challenges and highlights progress, partnerships and capacity estimates driving Saudi Arabia’s CCS ambitions. The analysis notes timelines, feasibility studies and the role of hydrocarbons in transition.

- https://www.gevernova.com/news/press-releases/qatarenergy-and-ge-to-develop-carbon-capture-roadmap-and-low-carbon-solutions-for – GE Vernova’s press release documents a memorandum of understanding with QatarEnergy to develop a carbon capture roadmap and low‑carbon solutions for Qatar’s energy sector. It states QatarEnergy’s updated sustainability strategy aims to expand CCUS capacity to over 11 million tonnes per annum by 2035, exploring a world‑scale carbon hub at Ras Laffan and integrating hydrogen, ammonia and CCS. The release outlines collaborative work on feasibility studies, pilot technologies for gas turbines and potential use of ammonia and hydrogen in decarbonisation, emphasising Qatar’s strategic ambition to reduce LNG carbon intensity and scale industrial decarbonisation. Plans include joint feasibility studies and pilots.

- https://www.modernpowersystems.com/news/drax-to-trial-pioneering-new-carbon-capture-technology-9705575/ – Drax Group reports trials of MOF‑based carbon capture at its North Yorkshire CCUS incubation site in collaboration with Promethean Particles and the University of Nottingham. Project MONET and related pilots test metal‑organic frameworks as solid sorbents that adsorb CO2 from biomass flue gas; MOFs promise lower regeneration energy than liquid solvents and modular, compact units. Government innovation funding supported prototype testing, with targets to demonstrate capture rates and assess techno‑economic performance. The articles stress that MOF trials are at incubation scale and further scale‑up, durability testing and cost validation are required before commercial deployment. Results will inform future BECCS proposals.

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative presents recent developments in carbon capture technologies, with no evidence of prior publication. The earliest known publication date of similar content is within the past week. The report is based on a press release from the American University of Sharjah, which typically warrants a high freshness score. No discrepancies in figures, dates, or quotes were found. The inclusion of updated data alongside older material is noted, but the update justifies a higher freshness score.

Quotes check

Score:

9

Notes:

Direct quotes from Dr. Steve Griffiths and other experts are unique to this report, with no identical matches found in earlier material. This suggests potentially original or exclusive content.

Source reliability

Score:

7

Notes:

The narrative originates from a press release by the American University of Sharjah, a reputable institution. However, the report is published on Carbon Herald, a platform that aggregates content from various sources. While the university’s credibility is strong, the platform’s reliability is less established, introducing some uncertainty.

Plausability check

Score:

8

Notes:

The claims regarding advancements in carbon capture technologies align with ongoing research and industry trends. The narrative includes specific details about ADNOC’s investment plans and pilot projects, which are consistent with other reputable sources. The language and tone are appropriate for the topic and region, with no inconsistencies noted.

Overall assessment

Verdict (FAIL, OPEN, PASS): PASS

Confidence (LOW, MEDIUM, HIGH): HIGH

Summary:

The narrative presents recent and original content based on a reputable institution’s press release. While the platform’s reliability is less established, the information aligns with current industry developments and includes unique quotes, supporting a high confidence in its credibility.